Y341-115 hole cleanout water injection packer is a separated layer water injection packer capable of indirectly flushing. Because of adopting a three-stage hydraulic cylinder structure, the sealing of the pack-off element is more reliable, and its initial sealing pressure is smaller only at 1MPa, so the resetting can be easily realized after moved, that is the most characteristic of the packer.

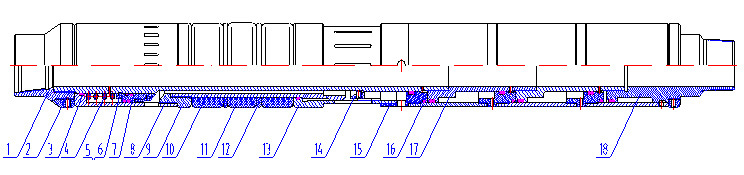

1.Upper Connector 2. Central Pipe 3. O-shaped Sealing Ring 4. Spring 5. Backing Ring 6. Fixed Collar 7. Well Cleanout Valve Plug 8. Well Cleanout Valve Sleeve 9. Packer Rubber Connector with Valve Face 10. External Central Tube 11. Packer Rubber 12. Spacer Ring 13. Press Cap 14. Deblocking Ring 15. Piston I 16. Hydraulic Cylinder Jacket I 17. Fixed Piston I 18. Lower Connector

I. Structure and Principle:

1. Structure:

The packer is composed of an indirect cleanout mechanism, a pack-off (packer rubber) sealing part, and a setting mechanism.

2. Principle:

1) Dropping: Well connect the packer according to the pipe string structure, and lower it down orderly in accordance with Underground Operation Instructions.

2) Setting: Pressurize from the oil tube, shear off shearing pins of the piston when the pressure rises to certain value (commonly at 3-4MPa), pressurize continuously until the three-stage hydraulic cylinder slides, and compact the pack-off element to seal the annulus space of the oil jacket and be locked by split claws. When the pressure of the oil tube is released, the pack-off element is still under compression state without retrieving, the setting process is finished as the sealing and compression state is continuously kept.

3) Sealing Inspection:

If it is of one-stage two-layer pipe string structure, the water distributor core at the lower part of the packer is fished out. By pressurizing from the oil tube, if the water return quantity of the casing is unchanged as before the pressuring or the pressure of the casing is unchanged as before pressurizing, that implies that the packer is sealed. If it is of two-stage or multi-stage pipe string structure, the water distributor core at the lower part of the first-stage packer is fished out, using the same method tests the sealing performance of the uppermost packer, while the sealing performance of other packers should be determined by the testing material.

4) Test and Separate Injection:

When in test, it is only necessary to replace the sealed nozzle of the water distributor core with required water nozzle for single-layer water injection, and to record the injection rate. If it accords with requirement of injection allocation, that shows this layer is qualified, conversely the water nozzle should be replaced until it is qualified, and then the other layers should be tested, the test is finished when all the layers are qualified. When in separate injection, it only needs to replace all cores into water nozzles which are tested qualified and then to inject water. (Note: Because the pressure of the oil tube is always higher than the pressure of the annulus space of the oil jacket when water is injected from the oil tube, thus the well cleanout valve is closed, and the pack-off element seals the annulus space of the oil jacket in setting. Therefore, the upper part and the lower part of the packer are separate without communicating; thereby the separate injection can be realized.)

5) Well Cleanout:

When it is necessary to clean the well, flushing fluid is fed from the annulus space of the oil jacket, because of the differential pressure, after the upper well cleanout valve is opened, the flushing fluid can pass through the packer from the annulus spaces of the internal and the external central tubes, then enters the oil tube from a bottom ball base and returns the mouth of the well, thereby realizing the well cleanout.

6) Deblocking: It is realized by lifting the pipe string up. Because the pack-off element attaches to and rubs with the casing, when the internal central tube ascends, the deblocking sleeve can be driven to move upwards and compact the split claws, then the split claws unlock the pack-off element. Under the resilience force of the pack-off element, the pack-off element retrieves away from the casing, so the packer is released.

7) Resetting:

After deblocking, the packer is lifted to another preset position, and is subjected to the resetting only by pressurizing from the oil tube. (If it is used with the eccentric water distributor, or the eccentric stopper is away from the working cylinder, the resetting of the packer also can be realized only by enough displacement, which has been proved in practice.)

II. Main Technical Parameter:

1.Max Outer Diameter (mm): 115

2.Min. Inner Diameter (mm): 54

3.Total Length: 1510mm

4.Connecting Threads on Two Ends: 27/8″TBG

5.Applicable Casing:51/2″(124-121)6

6.Sealing Pressure: Determined by index of the pack-off element (for example, sealing pressure is 25MPa if adopting 120℃, 25MPa pack-off element.)

7.Setting Pressure: ≧10MPa

8.Releasing Force: It is smaller, commonly less than 30KN

III. Notes:

1.Keep positions of the clamping points of the packer away from the casing coupling.

2.Should scrape the casing with the casing scraper before lowering the pipe string down, so as to prevent the pack-off element being damaged.

3.Carry out drifting with 116-1.5m drift size gauge before the pipe string is dropped, in order to guarantee the order installation of the packer (if the drift size gauge and the casing scraper work at the same time, the length of the drift size gauge can be shortened appropriately).

4.Clean the oil tube, and keep the oil tube and threads intact.

5.Ensure the filling fluid and flushing fluid are clean.