I. Application:

It is used in separated layer water injection, tests in formation testing and lifting technology, as well as any operation in which the pressure of casing is equal to or larger than the pressure of the oil tube.

II. Working Principle:

The packer is arranged at the preset position along with the designed pipe string. When a positioning convex lug is located at the bottom dead centre of a setting mandrel, the oil tube is lift to certain height and rotated to right, the pipe string is lowered down while rotating the torque to right, the friction pad stays immobile depending on the friction with the casing, the upper connector and the setting mandrel move down to push the sealing spacer ring, then the connector is sealed, the parts of the packer rubber and the mandrel move down, the cone body stretches the slips open to clamp the wall of the casing, the packer rubber is pressed in the annulus space of the oil jacket, at the same time, the bypass valve is closed, and the upper and the lower annuluses of the packer are sealed.

III. Deblocking: When the pipe string is lift up, the convex lug automatically moves upwards along the slope until to the releasing position of a J-shaped groove, the packer rubber is restored and is released.

IV. Technical Parameter:

Total Length: 1260mm

Max. Outer Diameter of Steel Body:Ф116mm

Min. Internal DN of Steel Body:Ф38mm

Free Diameter of Centralizing Body:Ф134mm-Ф135mm

Compacted Diameter of Centralizing Body: Ф116mm

Working Differential Pressure: Upper Pressure: 35MPa Lower Pressure: 15MPa

Setting Load: 10KN

Working Temperature: ≤150℃

Connecting Thread on Two Ends: 27/8 UPTBG

Applicable Casing Diameter: Ф121mm-Ф124mm

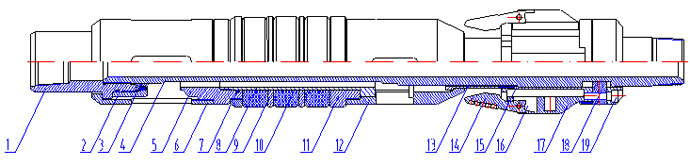

Y221 (PT) Packer

1.Upper Connector 2. Connecting Ring 3. Sealing Ring 4. Central Tube 5. Sealing Head 6. Outer Cylinder 7. O-shaped Sealing Ring 8. Outer Central Tube 9. Spacer Ring 10. Packer Rubber 11. Ejection Ring 12.Cone Body 13.Connecting Pipe 14. Slips 15. Centralizer 16. Spring 17. Centralizing Piece 18. Sliding Pin 19. Lower Connector

IV. Notes:

1.Use corresponding drift size gauge and casing scraper for drifting and scarping before the packer is descended into the well, and carry out the direct flushing.

2.Keep the descending speed not less than 20 seconds in well completion of pipe string after the packer is lowered down

3.Avoid forcefully lifting up and down in downhole, and well fix backup tongs for preventing midway setting.

4.Keep the setting position 1.5m or above away from the casing coupling and perforated well section in the well.

5.Carefully check whether weight indicator is safe, accurate, flexible and reliable before setting.

6.Carry out the magnetic positioning for the setting position of the packer if it is necessary.

7.Lift down the pipe string in the case of rotating the torque to right in the rotary setting of the packer, so as to ensure the reliability of setting.

8.Determine sealing inspection pressure of the packer according to technological requirements, commonly not bigger than 15MPa.

9.Check whether anchor rope, derrick and weight indicator are safe and reliable before deblocking, in order to avoid accidents.

Do not lift pipe strings up and down forcefully when encountering obstacles, and should contact with manufacturer as soon as possible.